Dash displacement in today’s vehicles can be a difficult situation to manage. While our tools today have increased power and capability, the newer vehicles we deal with usually leapfrog past the tool’s ability to manage certain tasks with ease.

With this in mind, we need to constantly look at ways to “defeat” vehicles to enhance our patient’s outcome. One such challenge we face is dash displacement; as vehicle construction methodology has changed and evolved, moving dashes have become increasingly problematic for us.

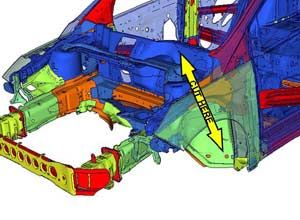

One of the safety features of today’s vehicles is their ability to readily absorb crash energy and take that energy and dissipate it and/or redistribute throughout the vehicle’s structure.

While this saves lives and helps in the reduction of injuries, think how this principle will effect our tool operations. The addition of dash reinforcement beams has made for difficult relocation or space making, but then the added issue of energy absorption makes “traditional” dash roll evolutions problematic.

Better solutions

Dash lifting evolutions make for better solutions in today’s vehicles but even these tool operations can be difficult if the vehicle is damaged severely or is a certain make. In order to make these dash displacement operations work better and give the rescuer the space needed, we need to add additional strategic cutting into the mix.

As part of our strategic cutting, we will need to create a vertical relief cut into the energy absorption or crush/crumple zone. This vertical relief cut allows us to isolate the dash when used in conjunction with the cuts of a dash displacement evolution.

This isolation gives us the ability to displace just the dash/firewall area, without “fighting” the rest of the vehicle structure. Where do we place these cuts? Well, first off we should be working on the nose of the vehicle, on the same side as the patient that is being extricated.

Image David Dalrymple |

The cut should be placed past the vehicle’s suspension or toward the passenger compartment. This cut allows the dash, when either lifted or rolled, to pivot or hinge and without the vehicle structure impeding displacement.

Our cut needs to be a little wider as well, so we do not “pinch” the crush zone and bind up. This evolution is effective, however, if we do some additional strategic cuts and/or spreads so we can make our dash evolutions and our door displacements easier as well.

Now, you maybe thinking, “Well, how do I get to this crush or crumple zone?” Basically, this focuses around removing or displacing the fender. In a fender strip evolution, we will displace the fender.

Starting at the point where the fender, door and A post meet, we place our power hydraulic spreader tips and begin a spreading operation. With this spreading motion, we want to control the movement of the fender out and away from the vehicle.

This will directly expose the crush zone as well as the door hinges and the wiring knockout hole in the dash area. Having all these items exposed will speed up our tool access for other displacement evolutions, and allow us to make our vertical relief cut easier.

Peel evolution

Another way to accomplish this is a fender peel evolution. With this evolution, we need to reach into the fender well and find the vehicle’s front suspension. We then take our power hydraulic cutter and make a vertical cut inline with the suspension, just cutting the fender.

We then make another cut horizontally near the bottom of the fender, close to the base of the A post and the rocker panel. Then, we grab the fender above the horizontal cut and pull it up vertically and bend it over the hood to move it out of our way.

A note of caution: some vehicles have reinforcement straps attaching the fender to the vehicle’s body so they might need to be cut as well. The fender peel also exposes the crush zone, door hinges and dash wiring knockout hole.

Image David Dalrymple |

Another key thing to remember is that during all of these fender evolutions, you must use caution when working around the vehicle’s suspension. It is bad to cut, crush or squeeze the vehicle’s suspension components.

Also, you will need to use caution when making your vertical relief cut if you cut through the hood area, as many vehicles today use gas piston struts to assist with lifting the hood and hold the hood up. Use the same precautions as when cutting through the hatch area in reference to gas struts.

Fender evolutions, while seeming minor in the grand scheme of the extrication process, play an ever increasing important role in our space-making operations. As vehicle technology impacts upon us in our tool evolutions, we need to constantly “think and work smart.”

We will need to revisit our tool evolutions and see in what ways vehicle materials, construction and design impact upon us and adjust our methodology to stay on top of the game.

Making space quickly and safely and taking into account for vehicle technology concerns will help us provide for better patient outcomes.